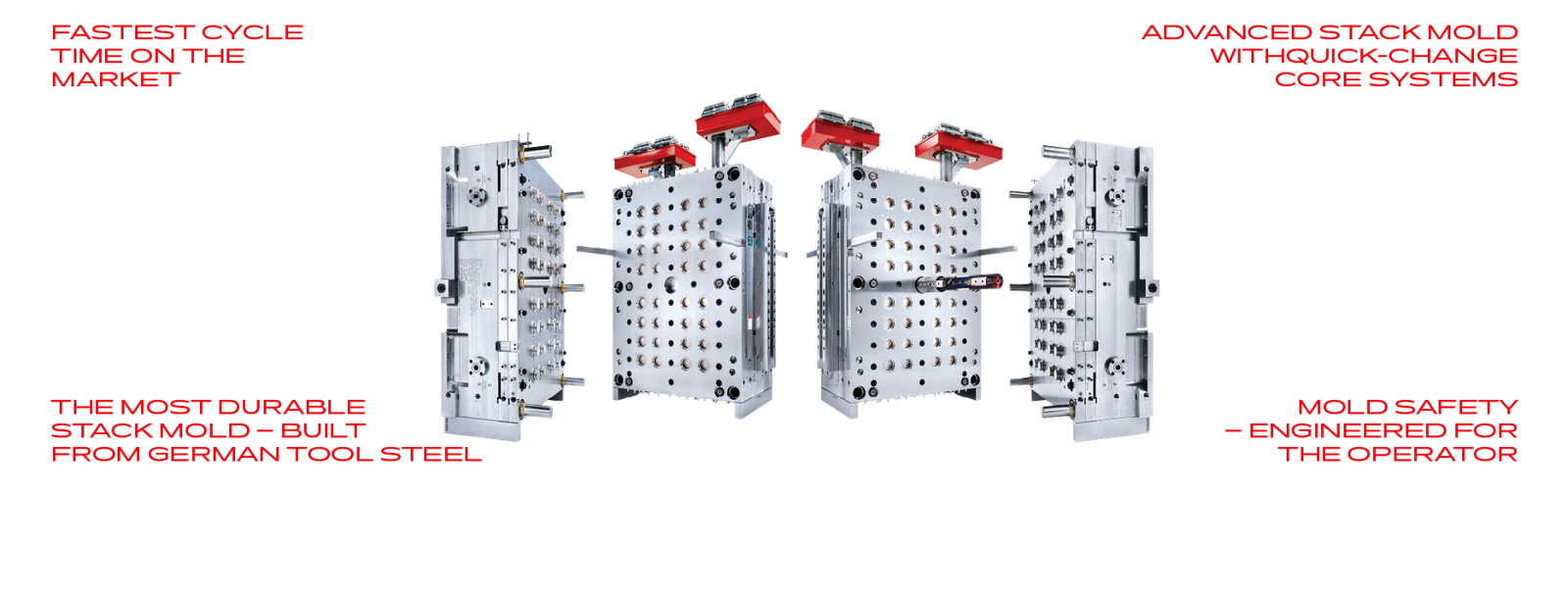

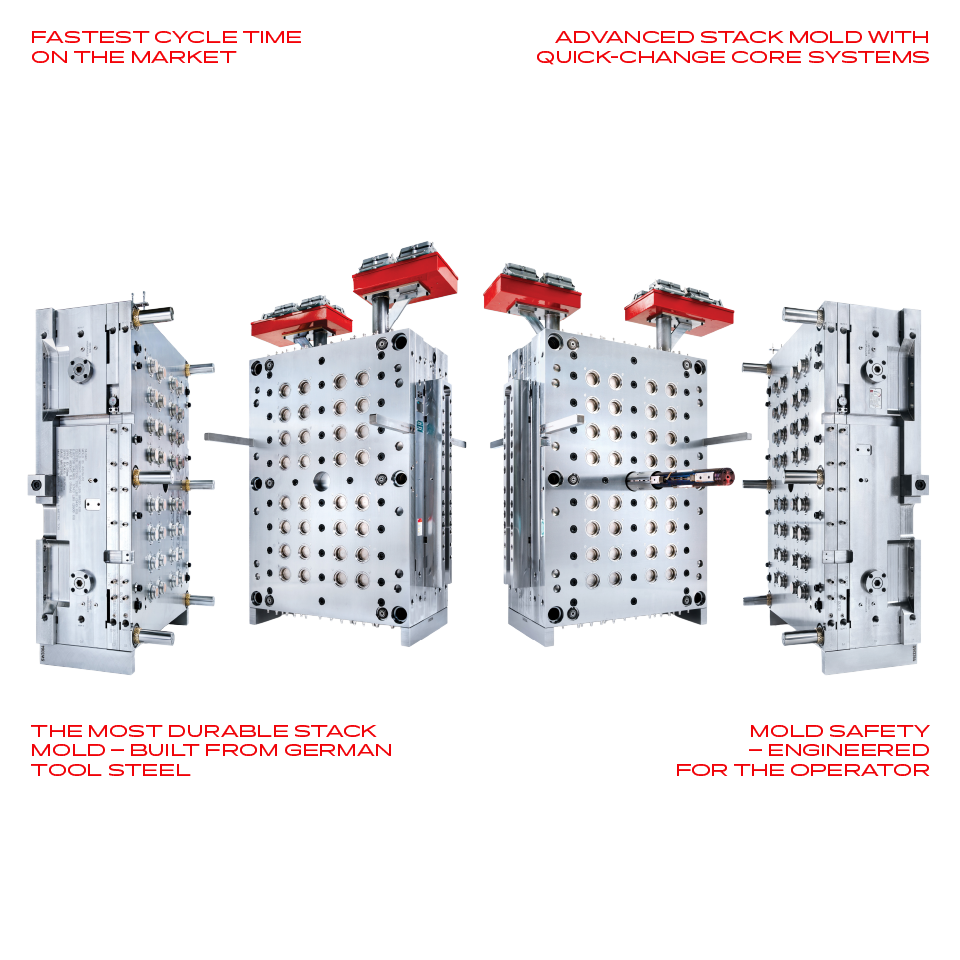

HIGH PERFORMANCE

INJECTION MOLDS

for more output in a shorter time

INJECTION MOLDS

for consumer packaging & personal beauty care devices

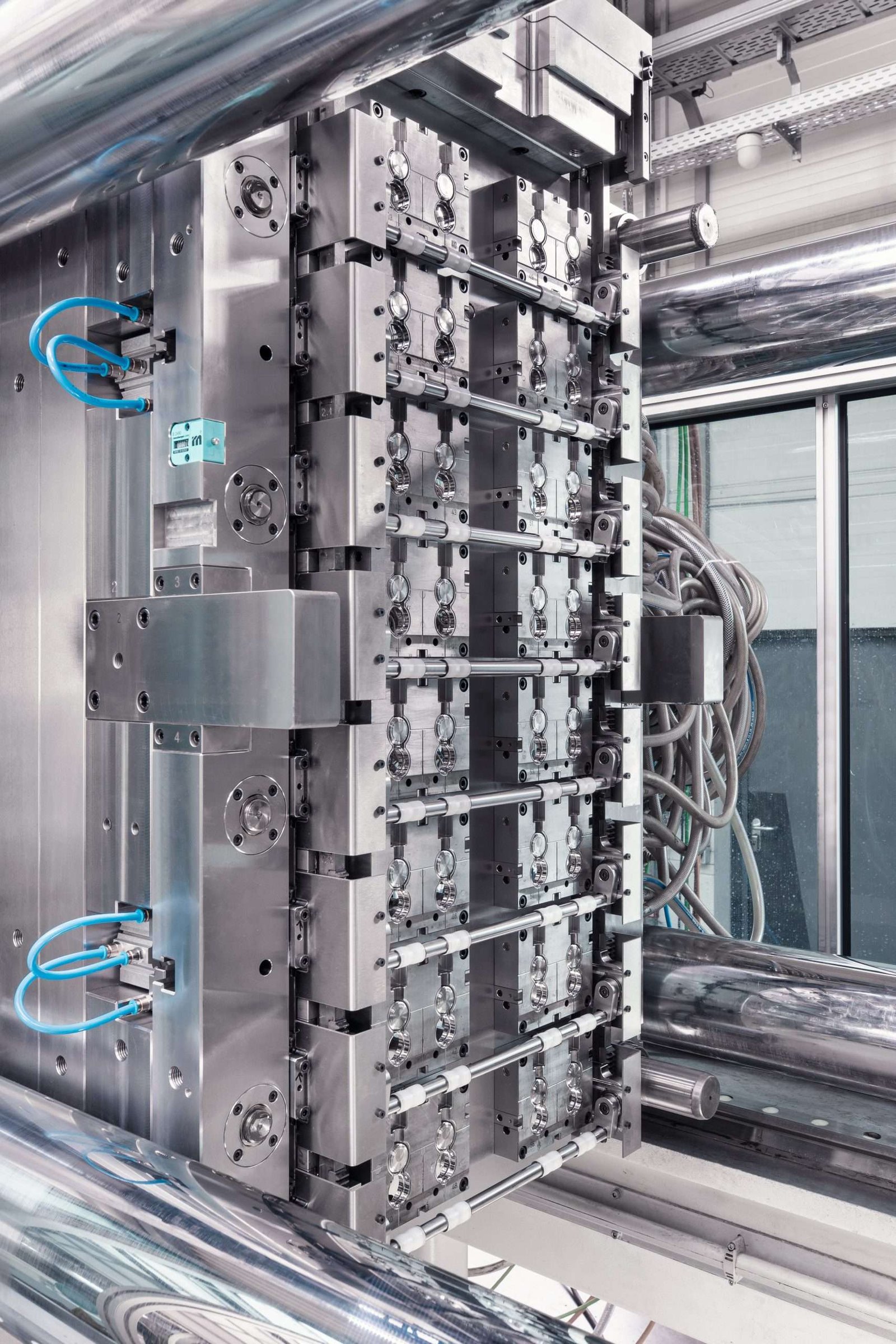

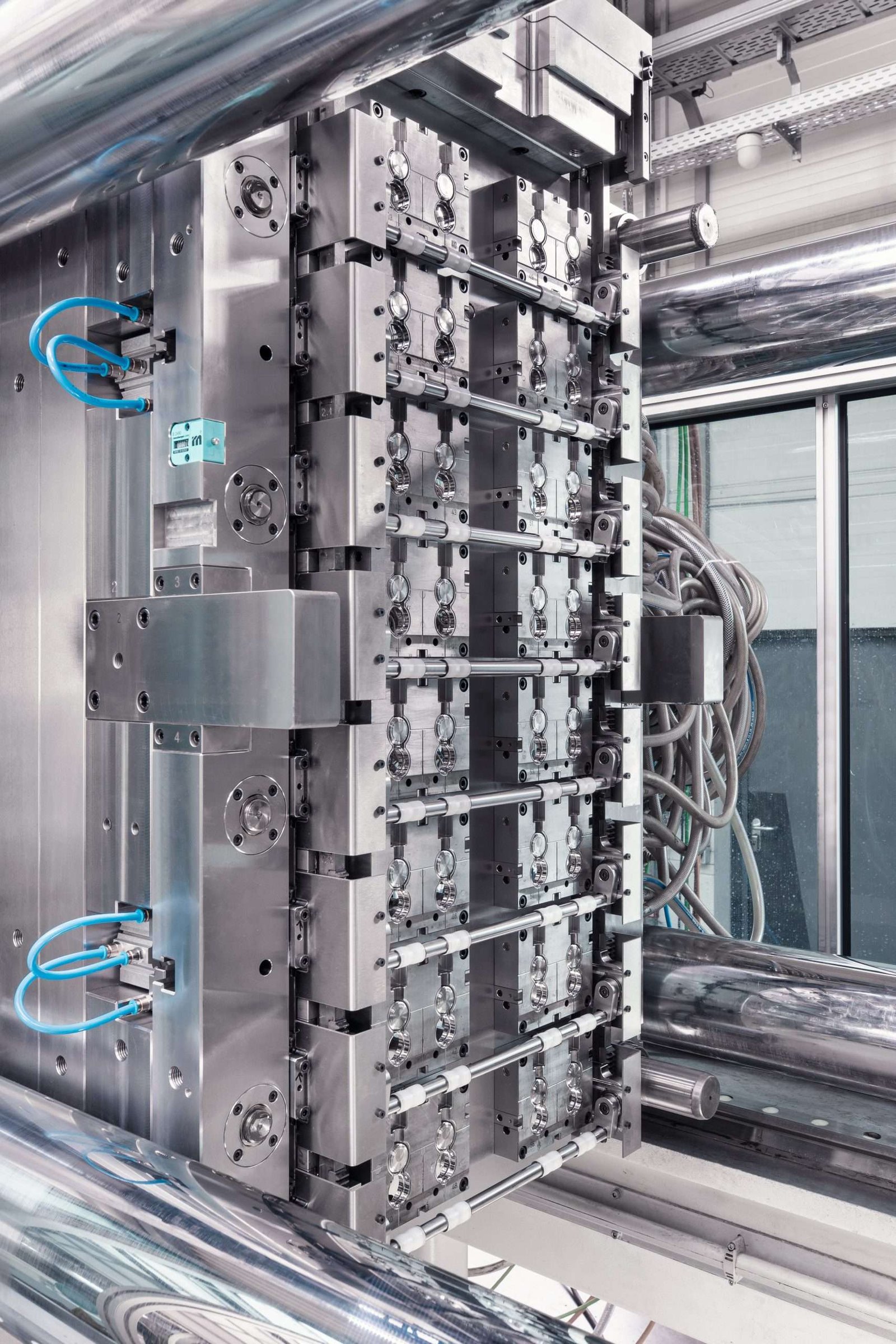

Erwes Reifenberg is a global player in the field of mold making. Our german company produces individualized high-performance molds with an excellent price-performance ratio for global customers— regardless of the industry or the size of the company. Our customers receive comprehensive global service for every project.

Get a first impression of our mold solutions for caps & closures, beauty & personal care and pharmaceutical & custom parts, shown here by way of example only.

PROJECT

RUNWAY

- excellent optics: separations on the article from the end customers and product consumers are not visible

- ideal mould processes and minimal maintenance through optimal coordination of the moving mould contour parts

- easy dismantling and assembly of individual parts are saving time and costs within your production (ER-quick maintenance principle)

Hover over the image to see the final product

PROJECT

HANK

- clean and quick article-covering via air cylinders

- ensuring trouble-free and long-term mould operation

- efficient and easy: Dismantling a cavity on your production machine

- ideal tool handling and implementation in your machine park ensured by efficient mould design

Hover over the image to see the final product

PROJECT

CREAM CAN

- highest production flexibility through modular structure of the cavity

- our high-speed mould ensures an extremely short cycle and cost-effective production

- article structure has a constant thin wall thickness

- precisely defined material pairings guarantee a very long mould life

Hover over the image to see the final product

PROJECT

FLUSH BOX

- part of a series that comprises 19 Moulds

- reduced cycle times (up to 50 %) through previous analyses and special use of alloys

- ideal tool handling and implementation in your machine park ensured by efficient mould design

- 0 % wall collapse through the special use of copper materials

Hover over the image to see the final product

PROJECT

BODY Q

- increases the (dimensional) accuracy of the article

- high customer satisfaction due to excellent long-term results

- guaranteed production reliability and dimensional accuracy

- robust tool construction ensures stable and smooth motion sequences

- optimal mould operation through exact guidance and control of the slide units

Hover over the image to see the final product

PROJECT

DUO ACTIVE

- compact tool design ensures optimal tool handling and efficient use in your machine park

- shortest cycle times through cooling within the slider and slide attachments

Hover over the image to see the final product

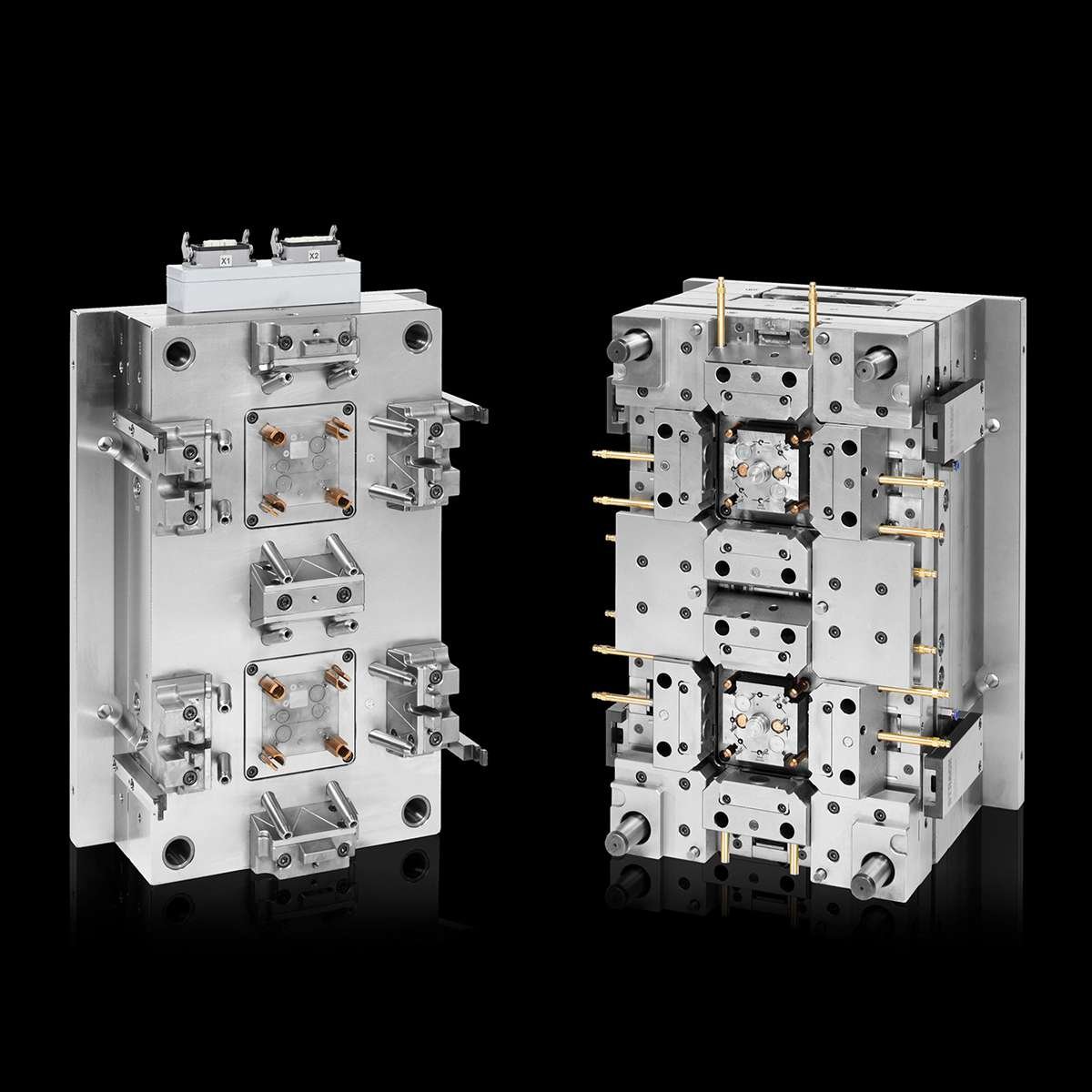

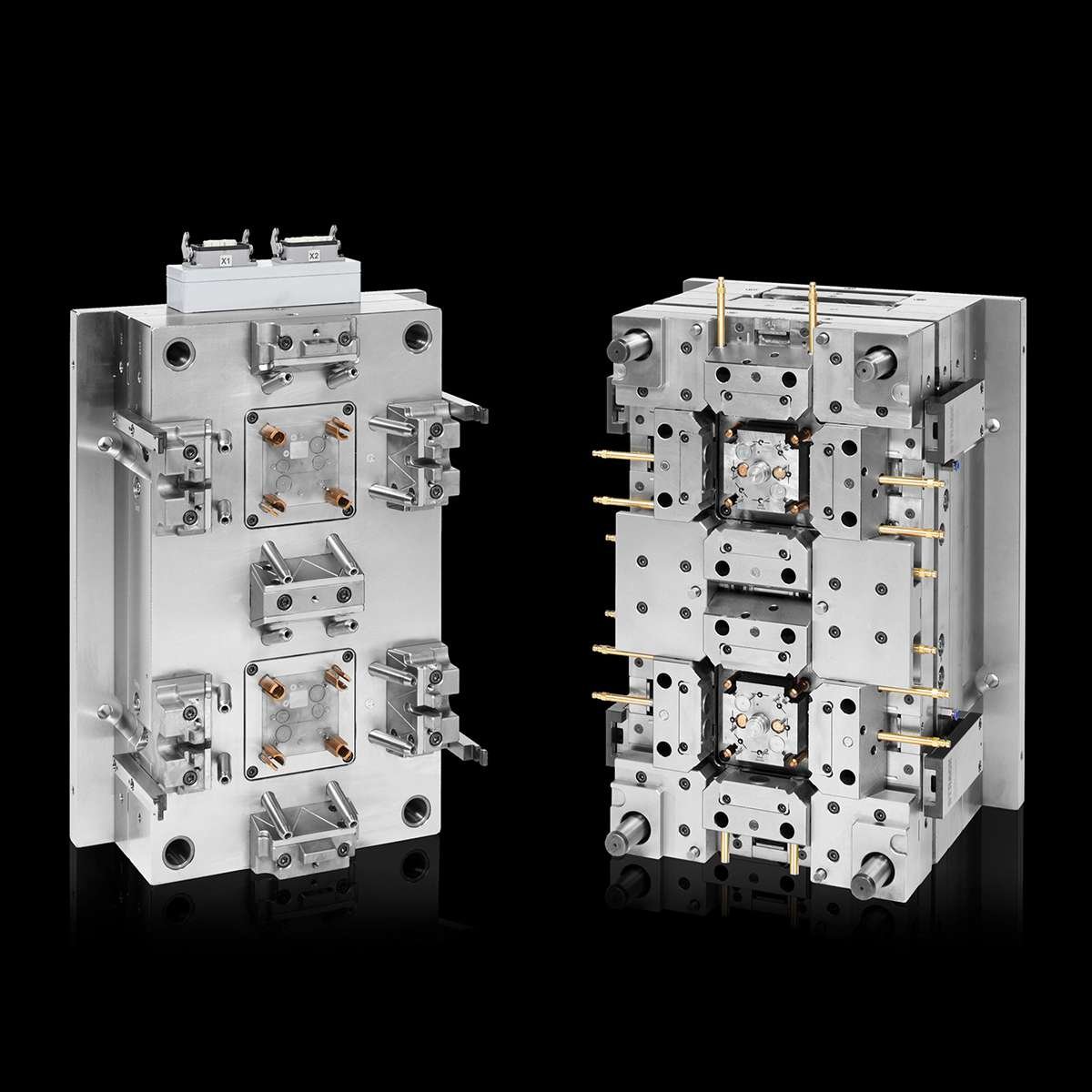

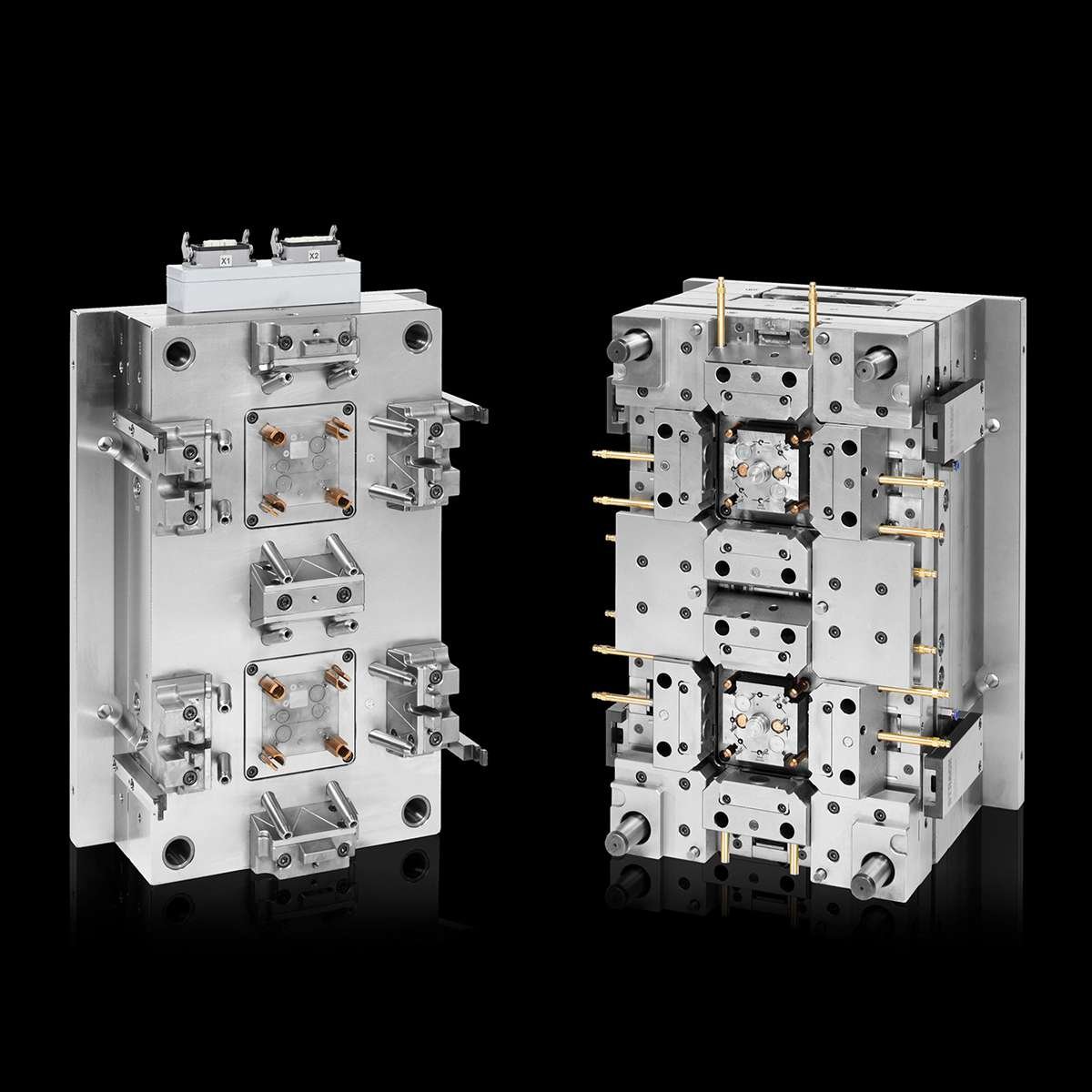

PROJECT

COMPULE

- remarkable cycle reduction through specially made cooling within the sliders

- dismantling of the components on our customer's production machine possible

- customers special design-requirement fulfilled: 4 + 4 compartment tool, left and right article in one mould

Hover over the image to see the final product

PROJECT

TWO PORT CAP

- ventilation support for each nest adjustable

- allows perfect demoulding

- article injection with two nozzles each on the article ensures perfect filling behavior on the article

- material pairings and coatings specially selected for medical technology

Hover over the image to see the final product

PROJECT

SCREW CAP

- part of the "ER medicine lock" assembly

- requested number of cavities on the customers machine exceeded and implemented

- result: cycle two seconds faster than specified and 10 % cost savings

- saved production-costs and -time through easy dismantling and assembly of individual parts

Hover over the image to see the final product

INTERESTED IN FURTHER

INFORMATION ABOUT US?

SHORT CONSTRUCTION AND DELIVERY TIMES

The know-how of our employees is an essential prerequisite for our innovative strength. Regular training, precise market observation and the integration of the most modern, future-oriented technologies are the basis of our performance.

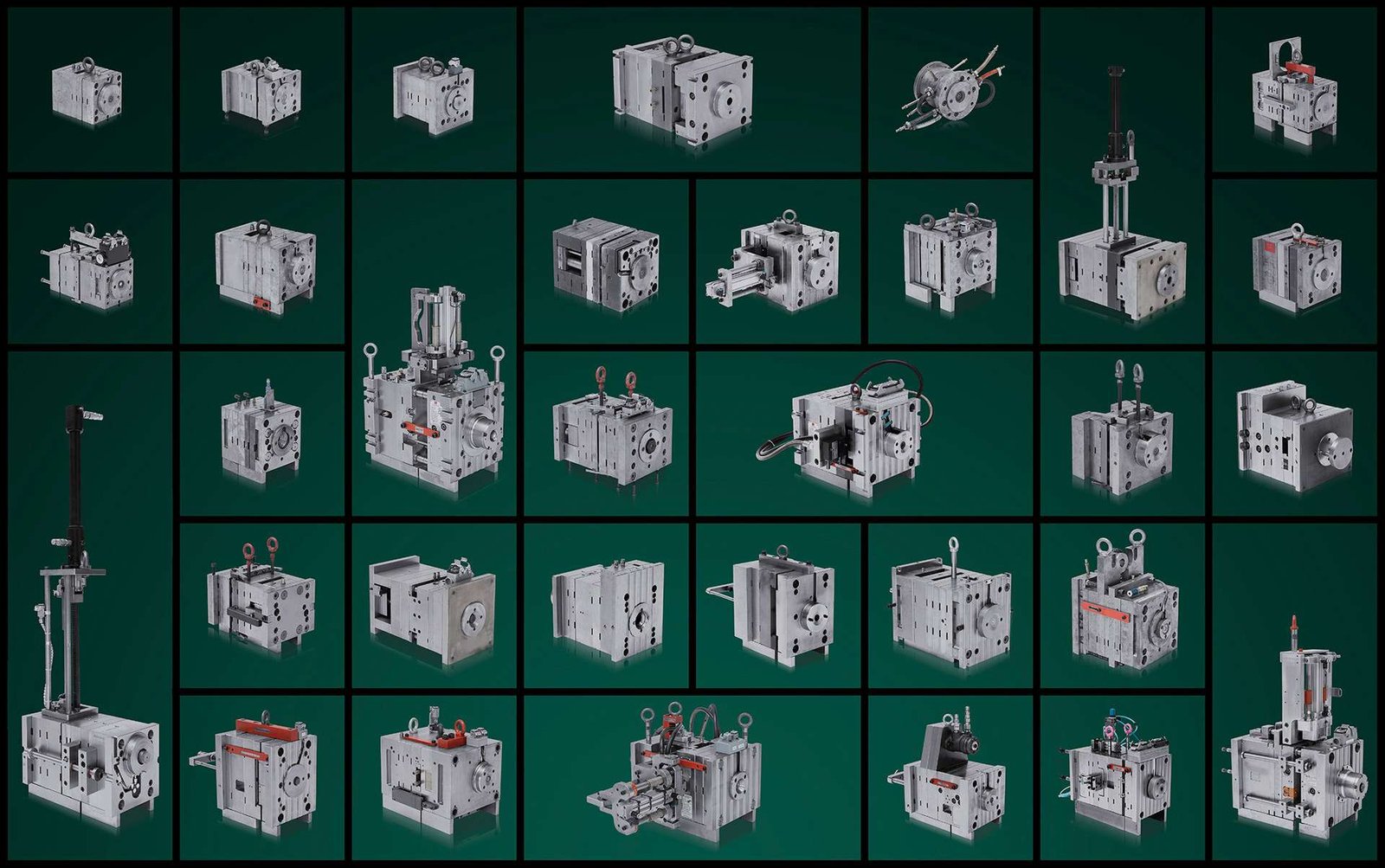

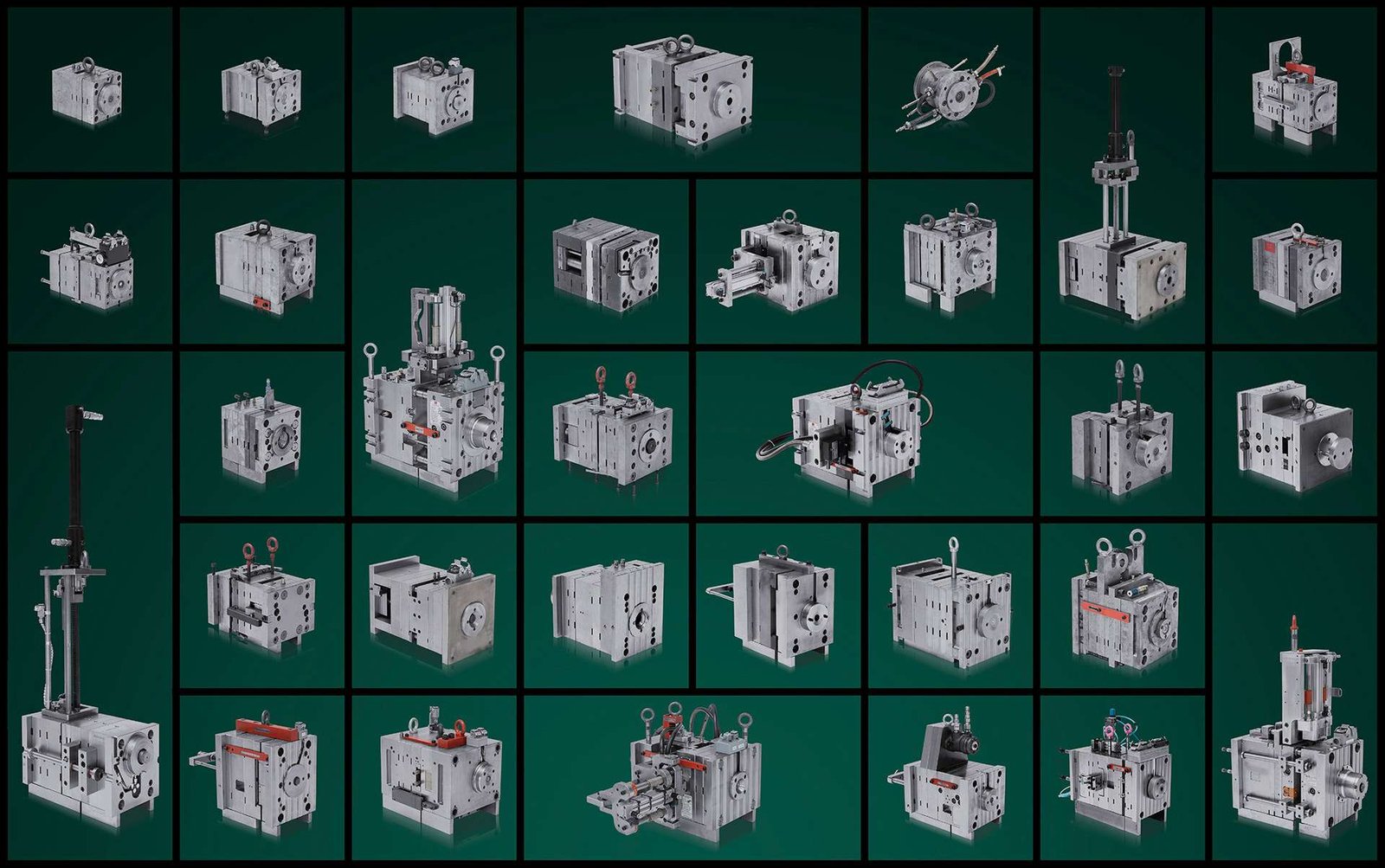

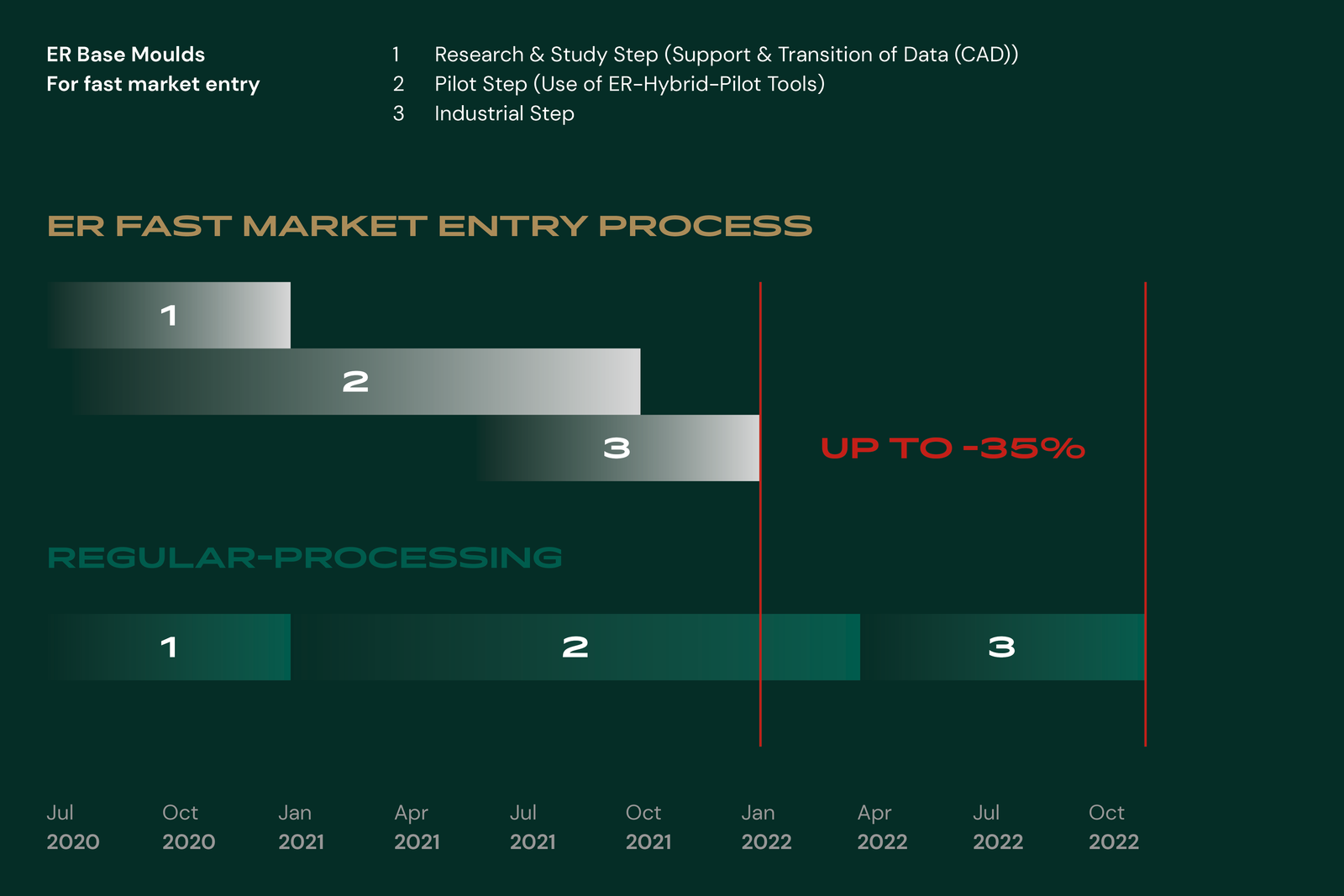

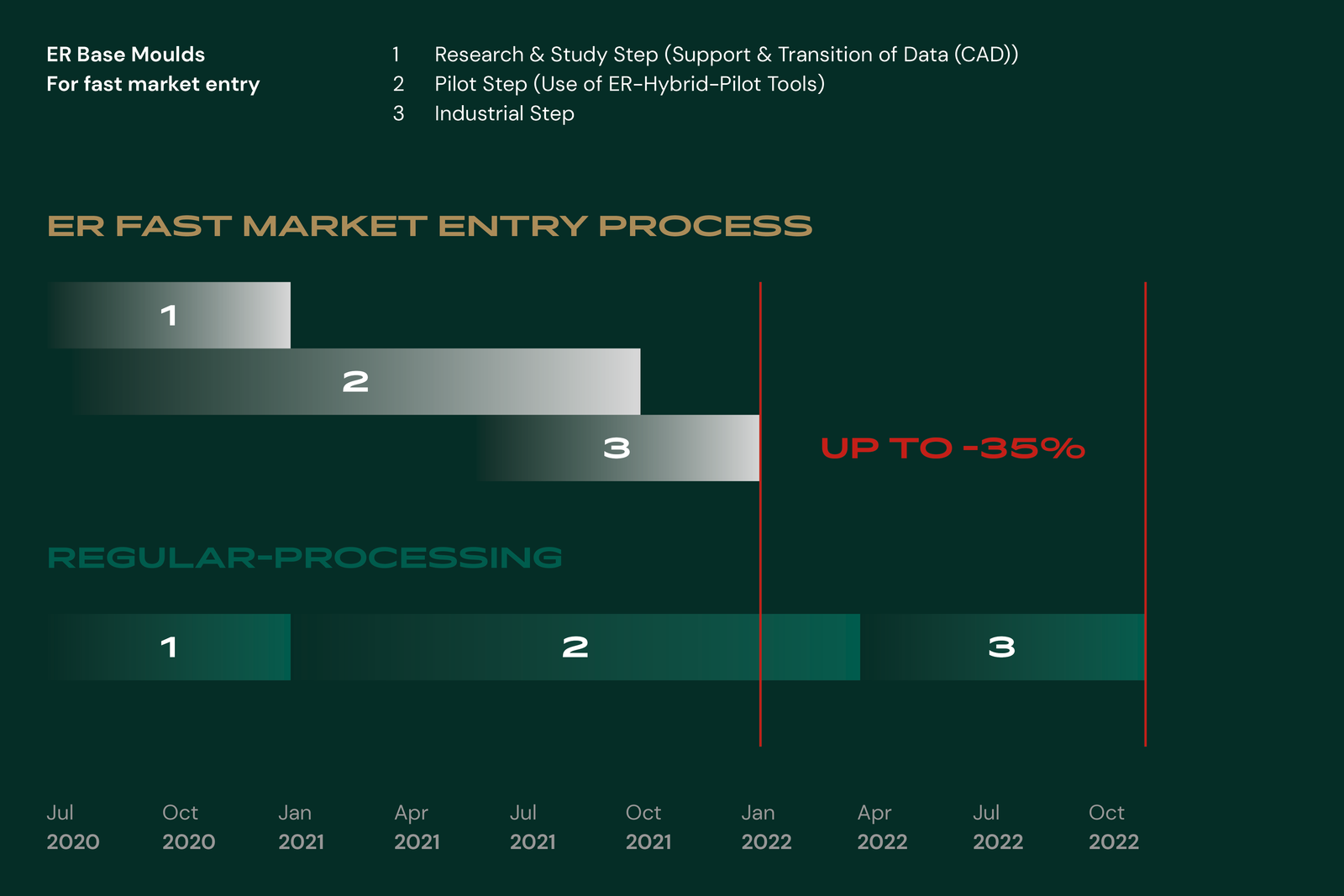

INHOUSE PROTOTYPING BASE MOLDS

Quickly available and standardized: our pilot-mold assemblies save time and costs. The variety of the ER-Base Molds is the perfect base for a quick and efficient market entry. Convince yourself and your customers now through our fast and field-tested pilot production: Test all mechanical functions of your article when you start a new project.

FAST MARKET ENTRY PROCESS

Improved manufacturing efficiency reduced production downtime

EFFICIENT PRODUCTION TECHNIQUES, SHORT SET-UP WITH PROFITABLE OUTCOME

- Exclusive use of the best and most reliable machine technology in the field of mold making with constant further development of production technologies

- Highly automated machine park

- Involvement of our employees with many years of experience

- Construction of the molds according to practical operation

WORLDWIDE IN USE – BUILT TO USE

MADE IN GERMANY

WORLDWIDE IN USE – MADE IN GERMANY

We are a global player in the field of special mold constructions and supply clients in over 90 countries.

HIGH QUALITY STANDARDS AND CONTINUOUS INNOVATION

Every mold is tested under production conditions in our Technical Centre and the contractually agreed specifications are verified and documented. Ongoing quality assurance is a red thread running through all activities of our company. We are certified according to ISO 9001:2015.

SUSTAINABLE THINKING AND ACTING

Global climate change and increasingly scarce resources determine our corporate philosophy. For many years we have been running a sustainability management system that encompasses the areas of raw materials, production and storage, logistics, disposal and staff training (DIN ISO 9001:2008).

GLOBAL SUPPORT AND ANYTIME ASSISTANCE

We strive to offer our customers assistance at all times. Our customer service team is ready to answer questions, provide technical support, and find solutions to challenges. We understand that our customers’ success is our success.

OUR CUSTOMERS

Eduard Wist

Bachelor Professional of Metal Production and Management at Jokey

We would like to praise the excellent cooperation we have with Erwes Reifenberg for so many years already. No matter where in the world Erwes Reifenberg tools are used in our factories, the cooperation is always problem-free.

Heiner Moeller

Plant Manager at Trimas Packaging

We have been working successfully with Erwes Reifenberg for decades and have completed many projects together. One of our oldest tools from the late 90s is still in use today, demonstrating the exceptional quality. We greatly value the long-standing, trusting, and transparent partnership.

Gerben Schepers

Managing Director at Ducona Holland B.V.

We have been a customer of Erwes Reifenberg for 30 years now and are consistently impressed by the tool technology and the accompanying services.

THOMAS LÜBBERING

Managing Director at FM Plast

FM has been working in partnership with Erwes Reifenberg for more than 40 years now. I am always amazed at how well Erwes Reifenberg understands their customers’ needs and how our wishes are promptly implemented in high-quality tool technology. The support in the development of new products is also great. As a supplier of articles in the packaging sector, we can only be successful for a long time with high-quality tool technology – this is possible with Erwes Reifenberg as a partner.

MR. LIWEA EDDINE LABIDI

Regional Purchasing at Henkel

As a large scale enterprise it’s important to have reliable partners globally. That’s because our major function is to coordinate our internal demand in different countries from one location. Therefore it’s absolutely necessary to invest in high tech injection moulds. We have to make sure, that we have downtimes which are low as possible, because we need to plan and calculate with the maximum possible output of our injection moulds. Out of this reason we work with our reliable injection mould supplier Erwes Reifenberg.

MR. KHALED DAJANI

Plant Manager at Arab Medical

We are working with Erwes Reifenberg for 23 years now, and we have implemented more than 30 projects during this period. From the professional article development, including corresponding functional analyses, to the project processing that runs absolutely professional and without any deviations in any case. All projects have been implemented successfully and we have trust in the quality and the long lifetime of the Erwes Reifenberg injection moulds. Also the spare part management and the fast reaction time of the after sale service is commendable. In any case, Erwes Reifenberg is a trustful and reliable partner for our success.

JOHANNES HILLE

Managing Director at AFK Kunststoffverarbeitung

We have been working for the pharmaceutical industry for many years.

Despite the known high requirements and the tight deadlines, we manage to satisfy customers to the fullest. Mutual competence, at Erwes Reifenberg and AFK, in mould making and injection molding, as well as the trust between us form the foundation for the sustainable success of everyone involved!

MR. BARRY ARMSTRONG

CEO – Managing Partner Embankment Plastics Limited

We have been working for co. Henkel as a converter for almost 20 years with the injection mold technology of the company Erwes Reifenberg

The reliability of the injection molds and all services are really exemplary.

MR. ISLAM ABDOU

Engineering & Projects Head AT NATPACK EGYPT

In order to achieve high efficiency, as a well-known producer of plastic articles, we also need a high degree of flexibility and reliability of our suppliers. In this respect, we are really grateful that we are working with Erwes.Reifenberg as a partner for our tool technology. In addition to the self-evident nature of high-quality tool technology, we are offered an exemplary service that is far above average.

Really recommendable !